MPETZn/AlH Metallized Film

■ Description:

Capacitor film,metallized film,metallized polypropylene film,metallized polypropylene film for capacitor,capacitor grade metallized film,metallized film for capacitor use,MPP film,metallized polyester film,metallized capacitor film,metallised capacitor films.

Coating a thin Al/Zn layer on the surface of plastic film, will get high self-healing Al/Zn metallized film for capacitor use.

The prominent feature of metallized film is its self healing ability. That is, when somewhere is breakdown, short-circuit current can make the film around the breakdown area melting and evaporation to recover its insulation property. Thus significantly reduce the impact on the breakdown strength by conductive defects and weakness in paper or film, thereby improving the working field.

Generally the thickness of the metal layer is 5nm-50nm, but on the international it can be 1nm-100nm. In terms of heat resistance, 1nm-100um is preferred, while consideration of electric properties, 5nm-50nm is more preferred.

Under the same evaporation conditions, the larger the coating thicknessδ, the smaller square resistance (Ω/□) , the smaller the resistance R, the greater the load current, while the worse self healing properties.

Al/Zn metallized film use heavy edge evaporation method, greatly reduce the contact resistance between the spraying area and the cores of the film capacitors, which has improved the quality of the capacitors.

■ Features:

Al/Zn metallized film has a better pressure resistance.

Al/Zn metallized film has a worse moisture resistance, easily oxidized.

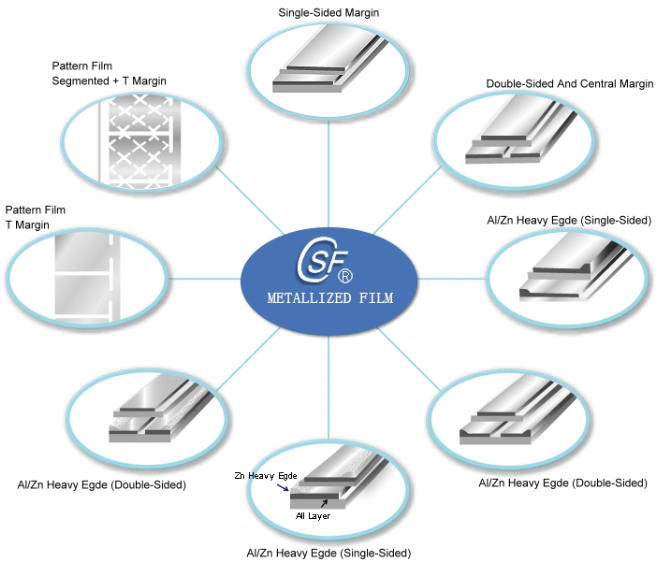

■ Types of Metallized Layer:

■ Cores:

1. Material:Plastic

2. Width:Film Slit Width±0.3mm

3. Inner Diameter:75mm +1.0mm/-0.5mm

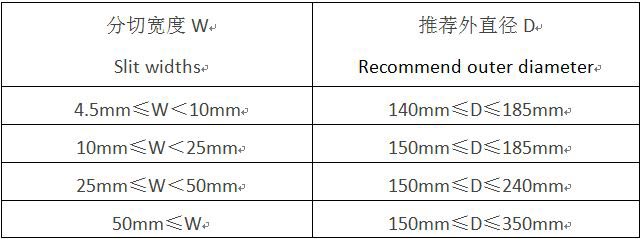

■ Roll Outer Diameter:

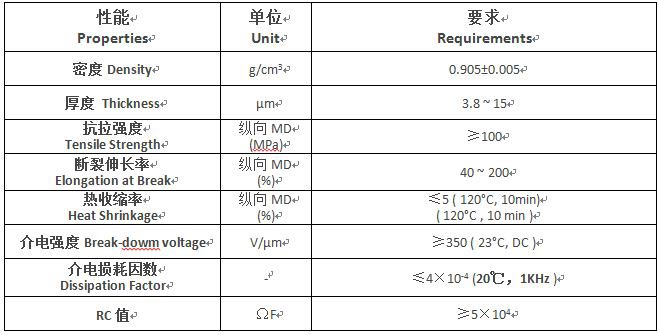

■ Specifications of MPETZn/AlH metallized film:

■ Packing:

1. Roll films are packed in vacuum plastic bag

2. Bags are marked with lables of types

3. The bags are packed in carton cases

4. The cartons are wrapped in wooden cases or reinforced carton

■ Storge:

1、Metallized film should be stored in its original package until its use with temperature 5 ~35℃and humidity less than 85%RH.

2、Metallized layer is easily oxidized when exposure to moisture. Therefore, the film should be used as soon as possible when opened.

3、The recommended temperature is 15 -25℃with humidity less than 60%RH after the package is open.

4、With original sealed package, and stored in the above mentioned conditions, the storage time can be as following:

Al metalized Film: 12 months from the delivered date

Al/Zn Alloy metalized Film: As Zn is relatively unstable, preservation period depends on the resistance of the film:

Less than 10 Ohms: 6 months (from delivery date)

10 Ohms to 15 Ohms: 3 months (from delivery date)

15 Ohms: 1months (from delivery date)

Vivien

Vivien