BOPP film

■Description:

Polypropylene film (PP) is formed by pouring, blow molding or biaxial stretching from polypropylene resin. Electrical BOPP film requires high technique, with the niaturization and high performance of components, in addition to thinning the thickness of the film, the high dielectric strength, high winding resistance, a good uniformity of thickness is also

required. These put special requirements on production process, higher requirements on equipment technology, process technology and production operators, it requires mature experience as well.

According to different production process, the PP film is divided into MPP, MRPP, RPP, RRPP four categories, among which MPP is divided into 01, 02, 03 three models.

MPP:Corona disposal polypropylene film, commonly known as the base film.

MPP01 is common film, with heat resistance 70℃~ 85℃, longitudinal heat shrinkage≤5mm;

MPP02 is quasi high-temperature base film, with heat resistance 70℃~ 85℃, longitudinal heat shrinkage≤3.6mm;

MPP03 is high temperature base film, with heat resistance 105℃, longitudinal heat shrinkage≤3mm;

MRPP: single-sided rough corona disposal polypropylene film

RPP: single-sided rough polypropylene film

RRPP: double rough polypropylene film

Surface roughening is increasing the surface roughness of the film, it is through transformation under different temperature by the monoclinic crystalαand hexagon crystalsβand form the mesh concave- convex rough surface on the base film surface.

■Cores:

-

Material:Plastic

-

Width:Film Slit Width±0.3mm

-

Inner Diameter:75mm +1.0mm/-0.5mm

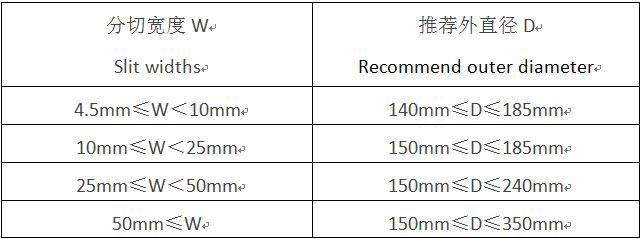

■ Roll Outer Diameter:

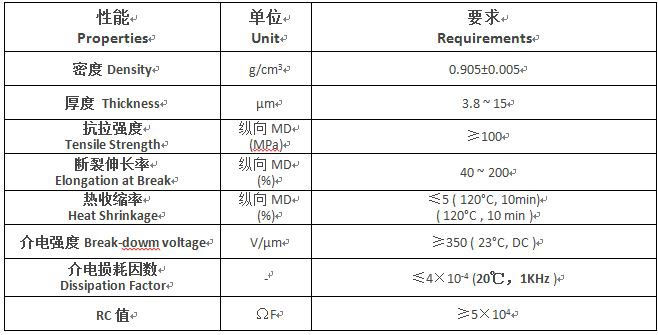

■ Specifications of BOPP film:

■ Packing:

-

Roll films are packed in vacuum plastic bag

-

Bags are marked with lables of types

-

The bags are packed in carton cases

-

The cartons are wrapped in wooden cases or reinforced carton

Vivien

Vivien